Everything under Control: The Importance of Post Welding Test

The sealing of welding of thermoplastic materials is essential. Satisfying the need for validation of welds requires appropriate tools: as is logical to expect, these are part of the offer of Leister.

Leister's experience in this segment is an excellent prerequisite for the careful design of suitable systems for assessing the quality of welds. We talked about these systems with Klaid Mastora, Leister's technical expert in machine maintenance and quality control.

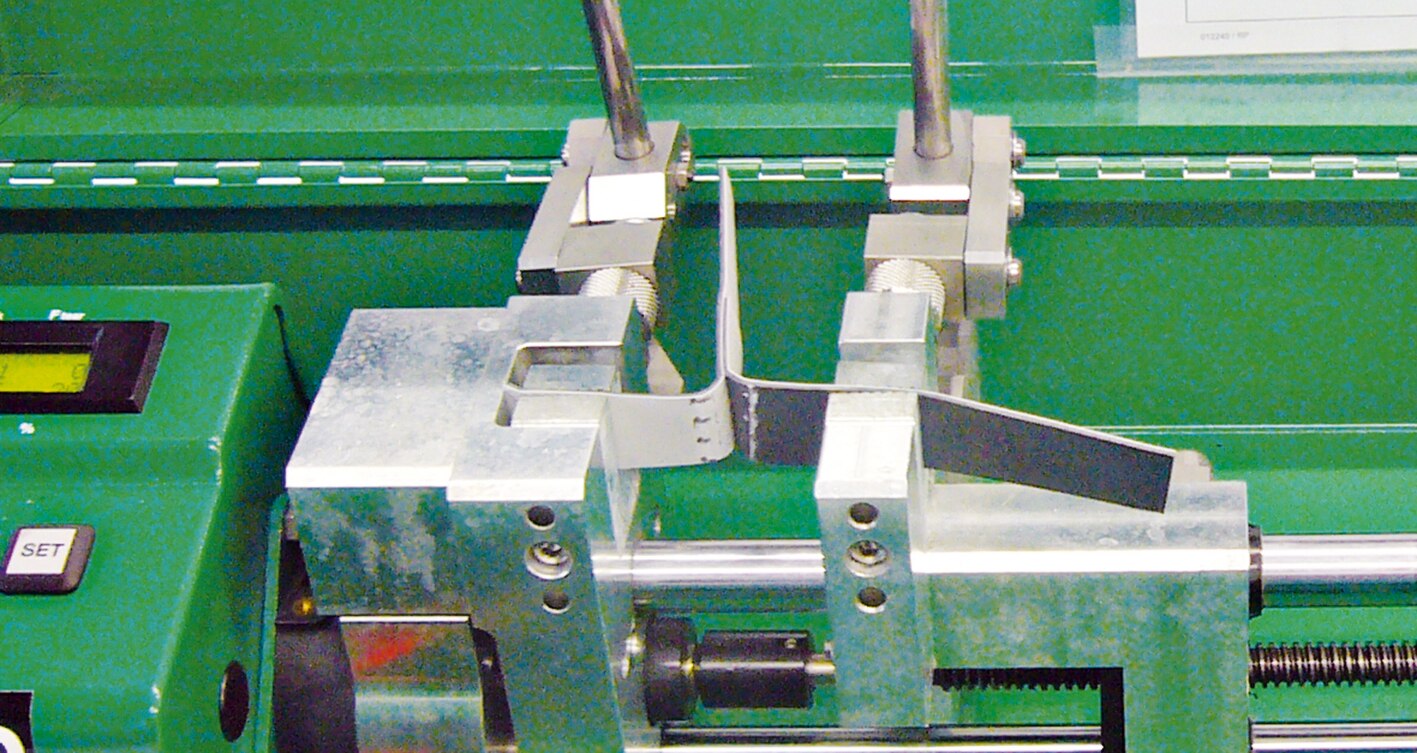

The breakout force values must remain within a precise minimum limit established according to the materials and the intended use of the weld. The appearance of what remains of the sample after tearing also provides the expert technician with useful information on the quality of the weld. Handy and light, Examo is a small portable laboratory that was created to be easily used on site.

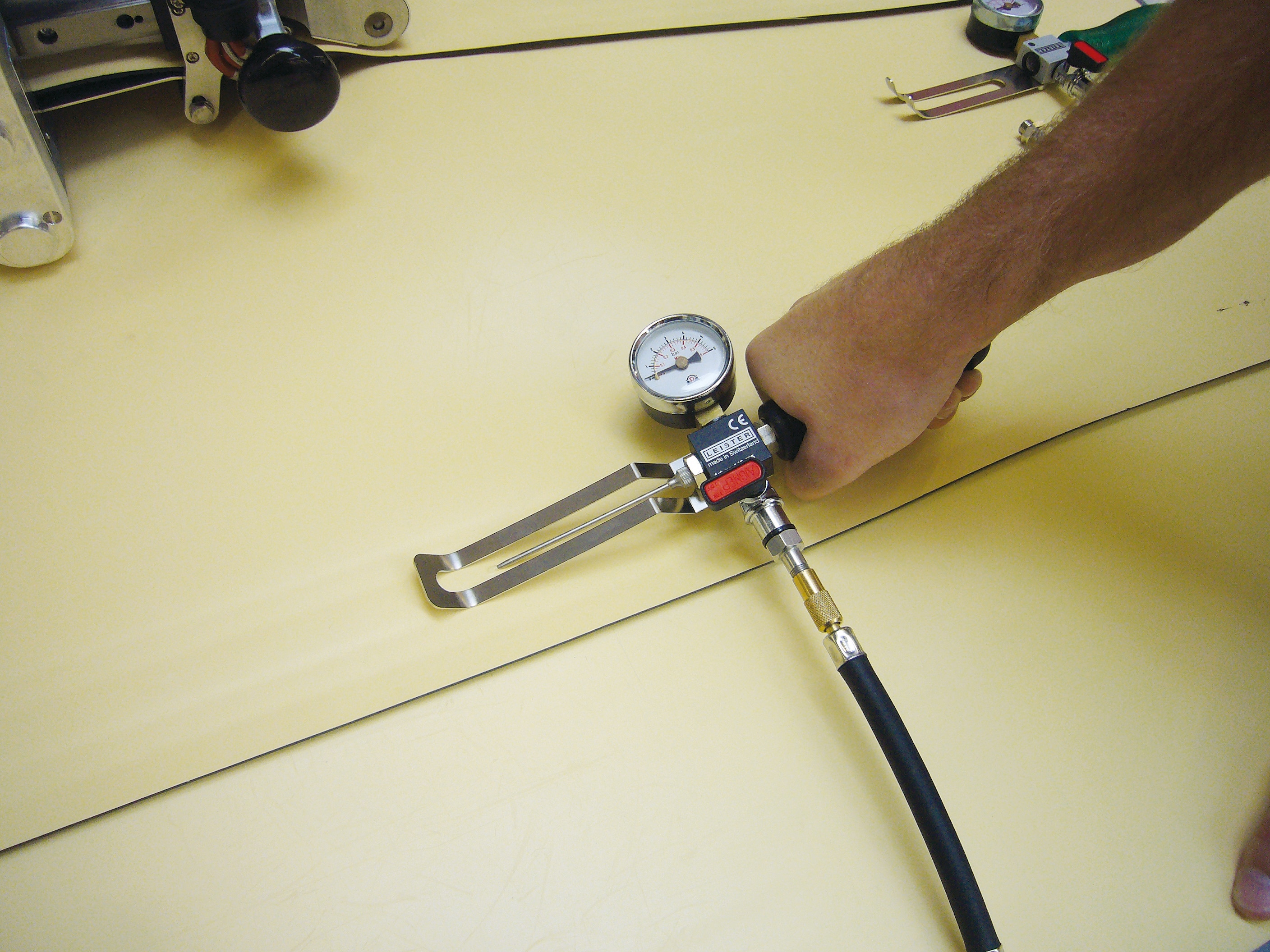

A compressed air pressure gauge and a TEST NEEDLE are used to test the seal of the weld. The needle is inserted into the weld where air is blown in until a certain pressure, measured with the pressure gauge, is reached. Then the pressure trend is monitored at specific intervals; the test is passed if the pressure drop remains within a range considered acceptable. The needle with pressure gauge is available in two different models according to the hardness of the material to be tested and a simple protection system avoids any risk to the operator.