Fast Drying of Paints on Beverage Capsules

Success Stories19 May 2020

For the recent development of a line of machines for spray painting and drying closures, both in plastic and aluminium, Omso has adopted the heaters produced by Krelus, a company of the multinational Leister group.

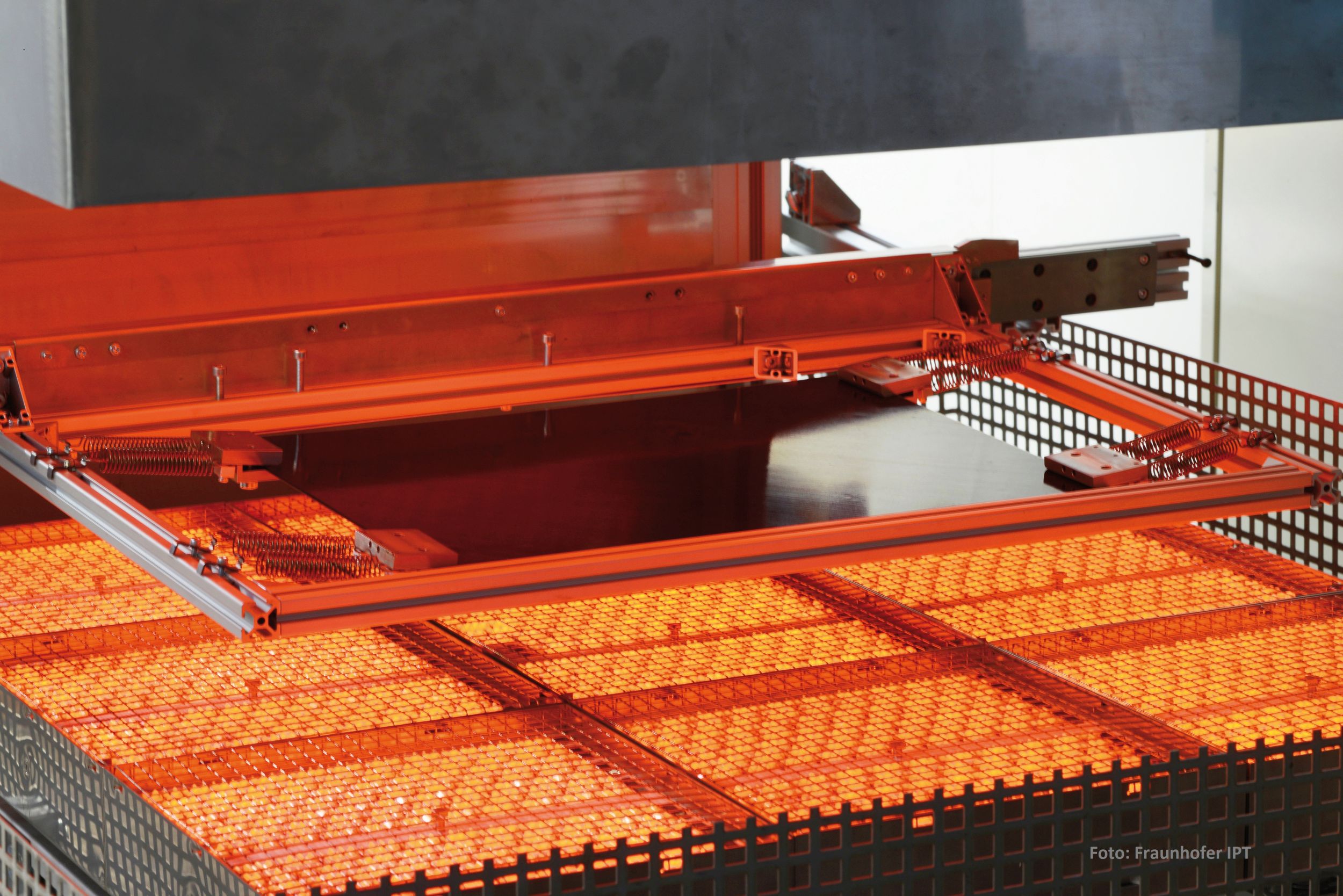

In the closures painting line, the drying part is set up around the Krelus modules. The closures exiting the spray booth enter the drying area consisting of four consecutive straight sections. Each of these sections consists of a "Krelus tunnel" with three heating modules, which allows a very short residence time compared to other forms of heating.