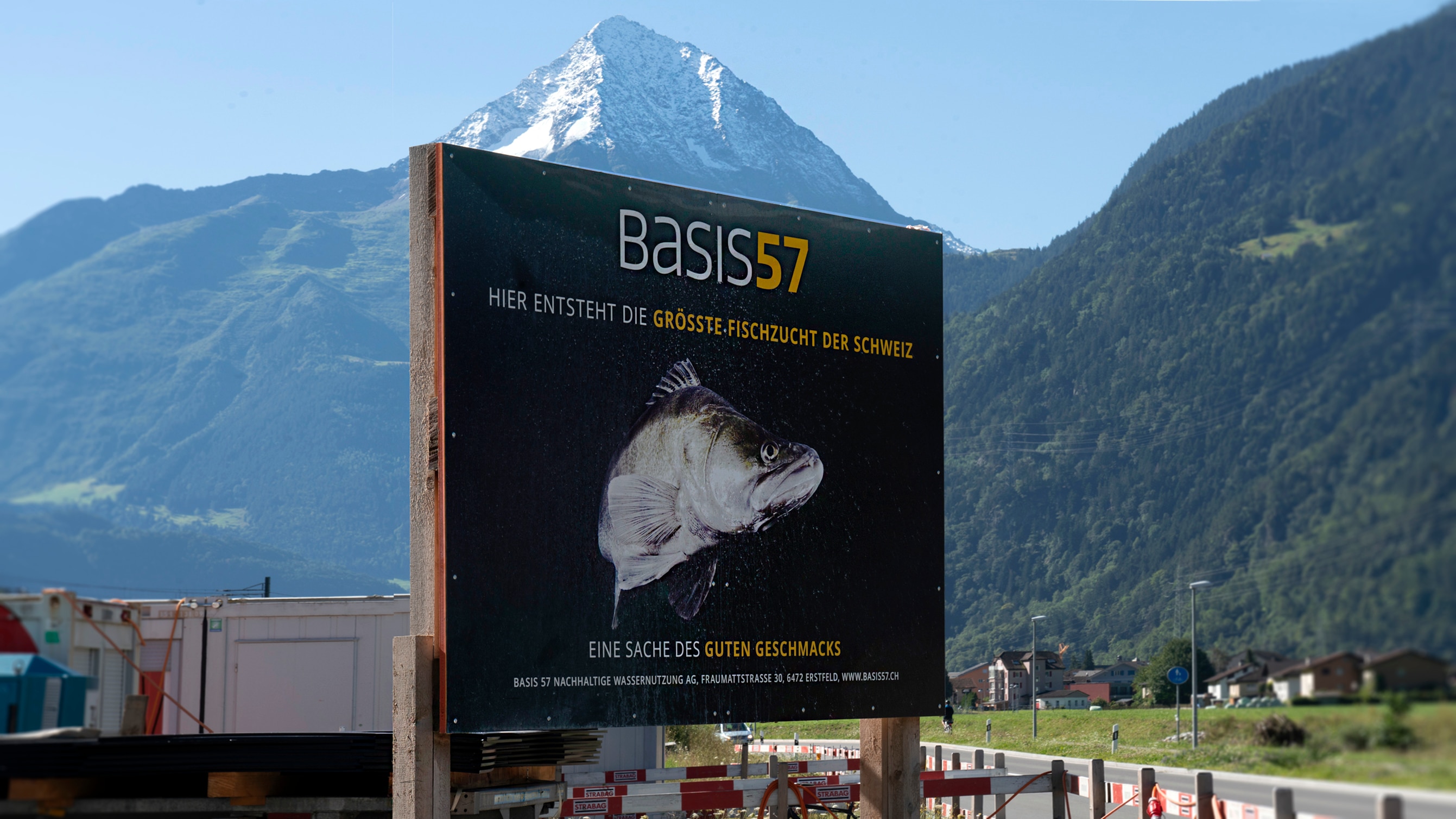

What do Tunnel and Zander have in Common?

At first glance, nothing. But there are similarities. In this blog post you can find out which and how Leister extruders are used for welding the huge PE tanks for the sustainable pike-perch breeding "Basis 57" in Erstfeld, Switzerland.

"PE pelvises fit in terms of stability and are also good in terms of price. In addition, PE has the advantage over concrete or other materials, making it easy for the fish tanks to be adapted more quickly if necessary, so we remain more flexible in operation.

In the video you can see how the PE fish tank from Colasit is welded with the Leister WELDPLAST S2 extruder. Specifically, the wall of the pool is welded to the floor so that the pool will later remain watertight and withstand the high pressure.

On this picture you can see that the blower motor of the WELDPLAST S2 is located at the head height of Piotr Kurys during welding. At 21 m / 68.9 ft. welding seam (the outer wall of the large fish tanks measures 21 m / 68.9 ft. each) and a welding speed of 25 cm/min. / 9.84 in/min., Piotr has about 85 minutes of "extruder sound" in his ear, if he doesn't take a break. No wonder he is pleased with the quiet Leister extruders.

Here is a photo of the finished breeding tanks. Soon zander fish will be swimming and growing up here in Erstfeld Uri in pure mountain water.