Hot Air Welding Compared to Solvent Welding

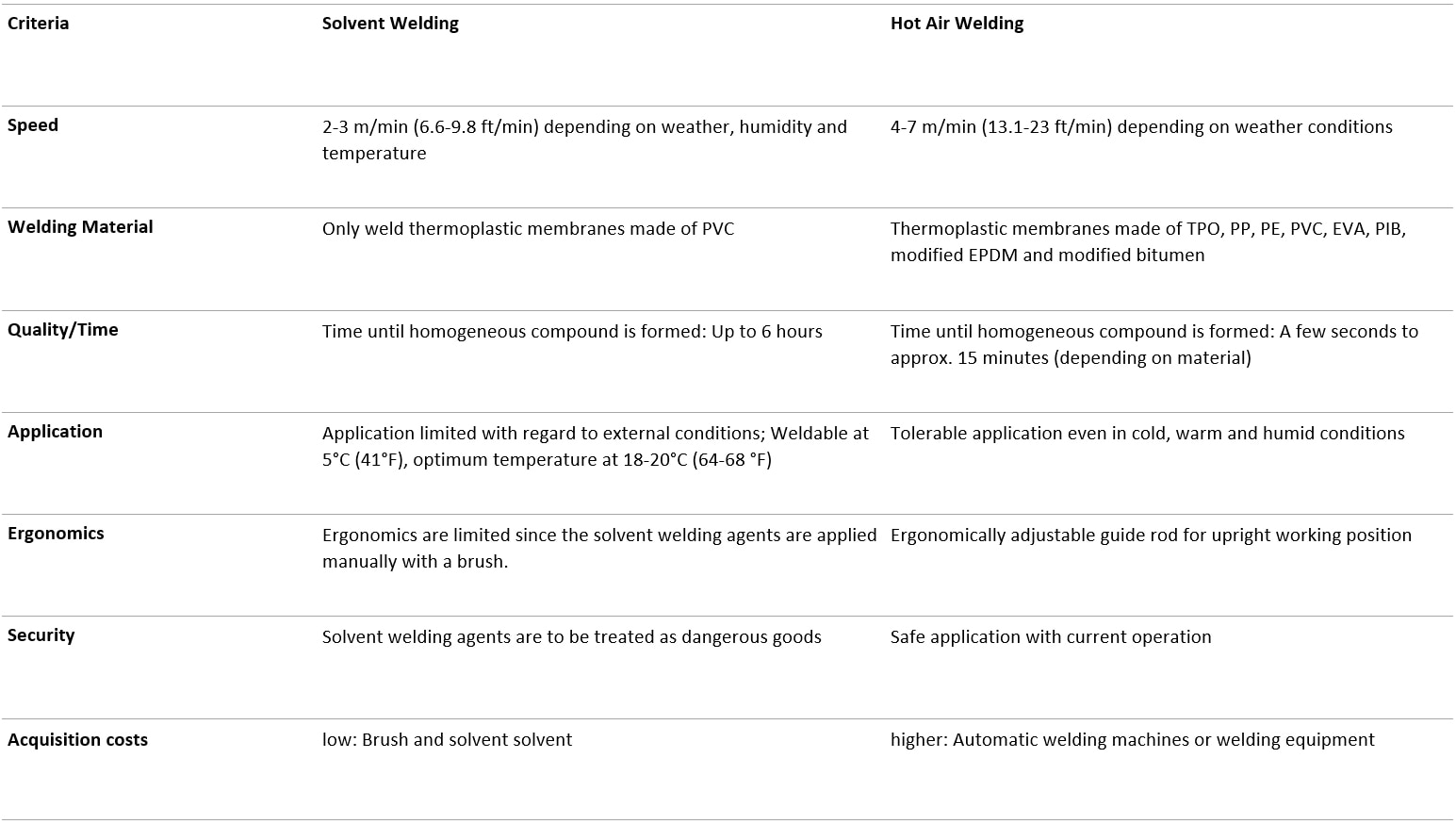

In this technical article, Leister's roofing expert, Roland Beeler, compares plastic welding techniques: hot air welding vs. solvent welding. This much in advance: hot air welding has many advantages.

Let's take one example: Overlap welding roofing membranes. Leister offers various automatic roof welding machines for this application. Using hot air, the membranes consisting of the plastics listed above or of modified bitumen, are tightly joined together in an overlap welding process. First, the membranes are heated with hot air at a temperature of approx. 400 °C to 550 °C / 752 °F to 1022 °F (depending on the material) until they melt. They are then pressed together firmly, creating a molecular, homogeneous bond in a matter of seconds.

We have also provided a video comparison.