Interview: Silke Landtwing, Corporate Communication Manager, Leister AG, Switzerland

From October 19th to 26th, the K 2022 trade show in Düsseldorf opens its doors to international visitors. What significance does K 2022 have for you personally?

When I started at Leister in 2015, the K-Trade Fair was the first global exhibition I attended with Leister. It is the platform for innovations and new trends. It is the leading show for the plastics and rubber industry. Also, it is a great opportunity for Leister to meet our global customers and partners and to present our newest innovations and developments. This year all our worldwide customers and partners are very welcome to join us in Hall 11 at booth E14 during these 8 days in Düsseldorf. I'm very excited to meet and talk to our customers and partners in person.

Which highlights and innovations are you going to present at the K 2022?

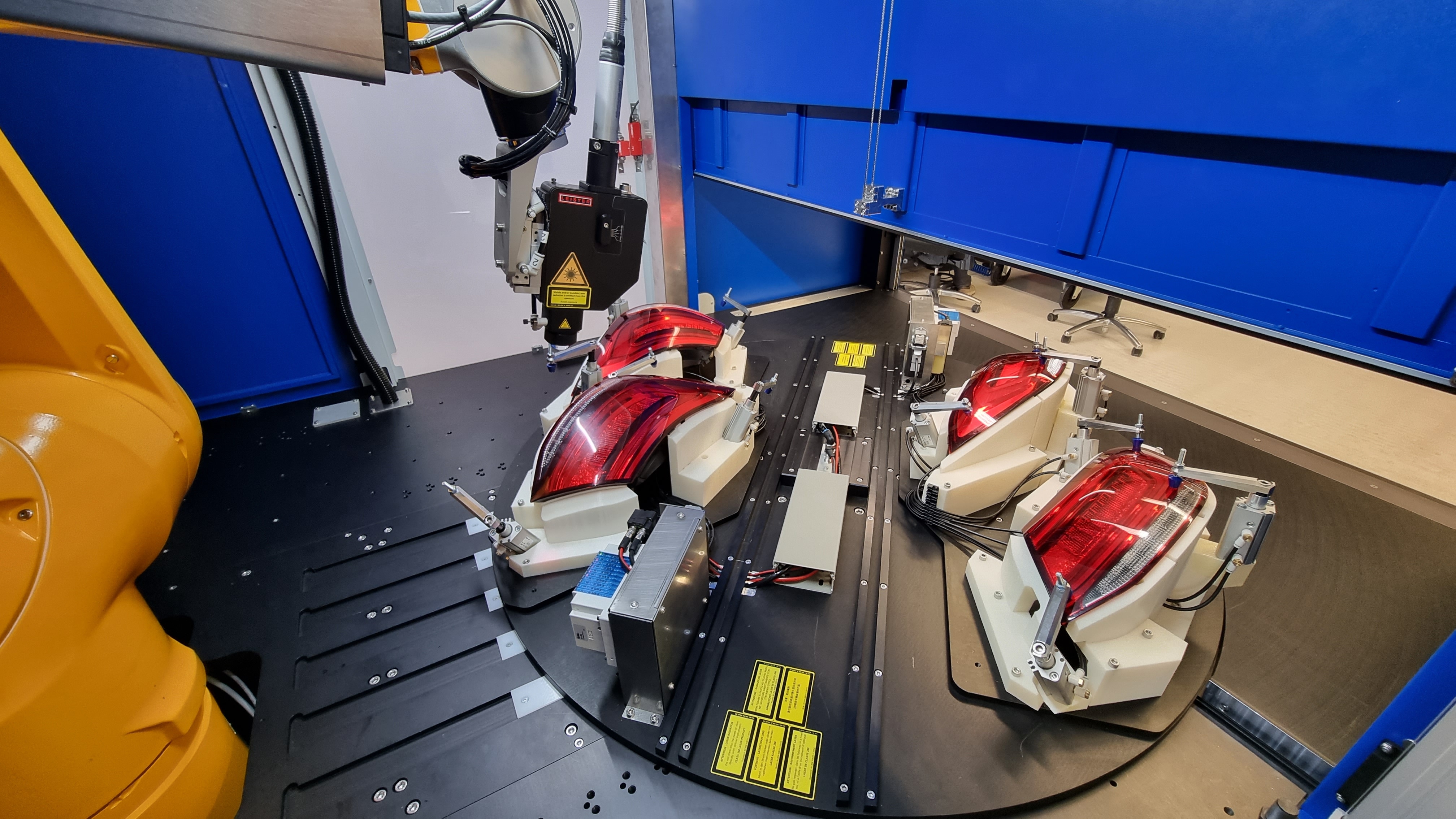

I am very pleased to announce that we will be showing our MAXI laser welding Turn-Key System for the first time. This is a world premiere. The MAXI laser is assembled in a modular way and designed for laser welding of large plastic parts. Applications include the welding of automotive taillights, bumpers, trim or large containers in the automotive industry. The laser welding system can also be used for welding technical textiles, for example for waterproof outdoor clothing or leisure sports equipment.

Tell us more about the MAXI

The laser welding system can be integrated into industrial processes and production lines and can be configured according to customer requirements. The MAXI laser can be tailored to the customer's specific application and equipped with the components required for the process, allowing easy configuration with different laser optics, clamping devices, motion systems, etc.