WELDPLAST 200-i and 600-i - different strengths

The WELDPLAST 200-i processes many different types of plastics, including plastics that are difficult to process.

The WELDPLAST 600-i is particularly powerful with an output of 13.2 lbs of plastic per hour, making it ideal for large machines and systems.

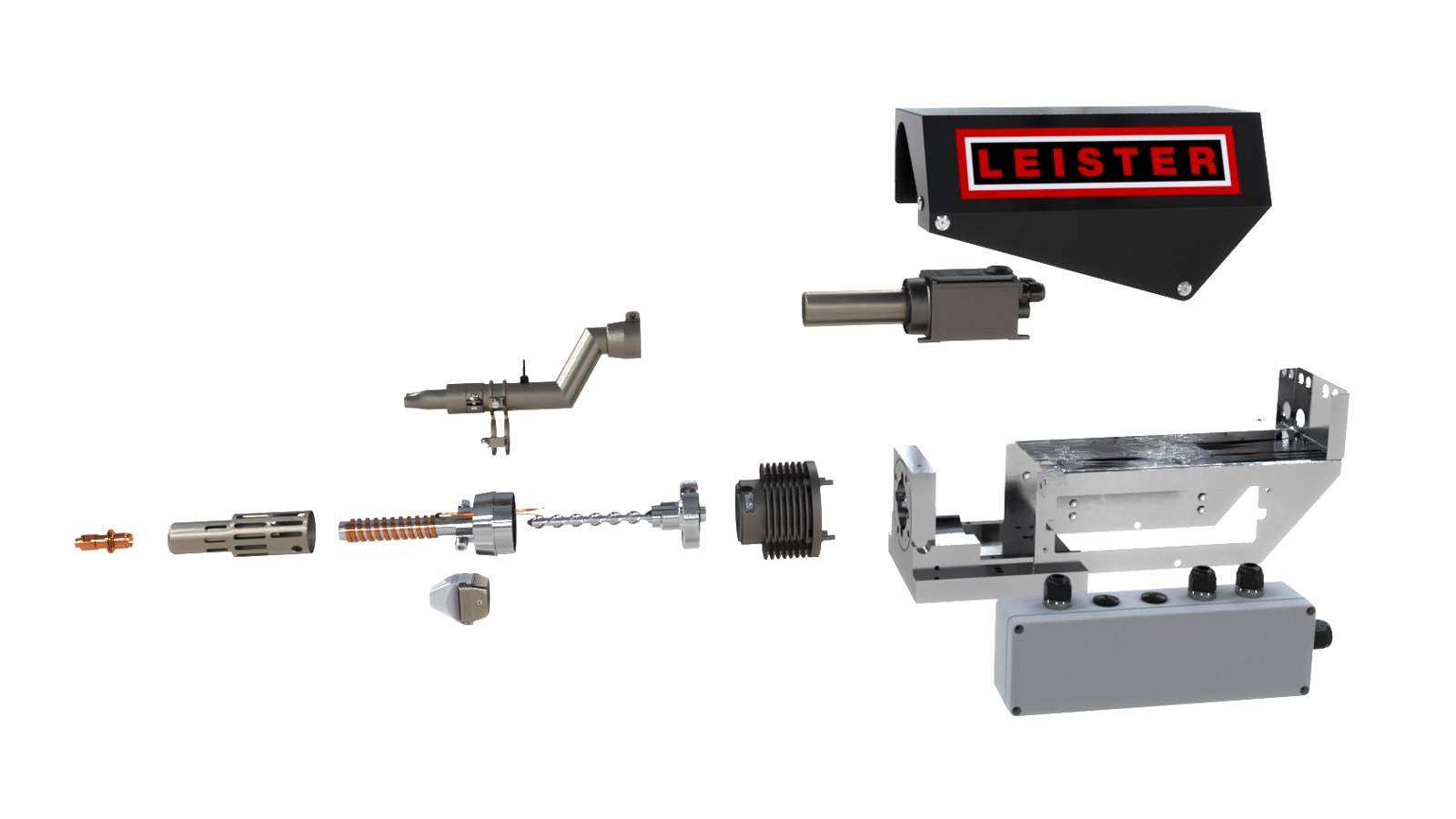

Individually selectable solutions

You select the appropriate drive and communication components for the extruder module individually according to application and need. If you install additional sensors, you can control and monitor your process as required.

Integration made easy

Electrical and mechanical adaptation points are already prepared on the extruder modules, allowing you to integrate the modules into processes that require preheated air, for example.

Modern industrial interfaces or analog interfaces are available for communication, which you can install in addition if required.

The most important advantages

- Automated: If you require extrusion welding or 3D printing in automated, continuous operation, WELDPLAST 200-i or 600-i is your solution.

- Controlled: Depending on the application and requirements, you have the ability to control and regulate parameters such as temperature and output with appropriate sensors.

- Modular: For your process, you select - as if from a modular system - the appropriate extruder module and simply add the appropriate hot air, communication and drive components.

- Individual: Depending on your requirements, you have the choice between two extruder modules, which you can adjust to your specific needs.

- Current: It goes without saying that all components comply with current industry standards and are subject to continuous development.

Questions/Guidance

If you have any questions about the WELDPLAST 200-i or 600-i and/or would like advice, please contact Reto Britschgi, Product Manager Extruder at Leister Technologies AG. He is our extruder specialist and will be happy to advise you.