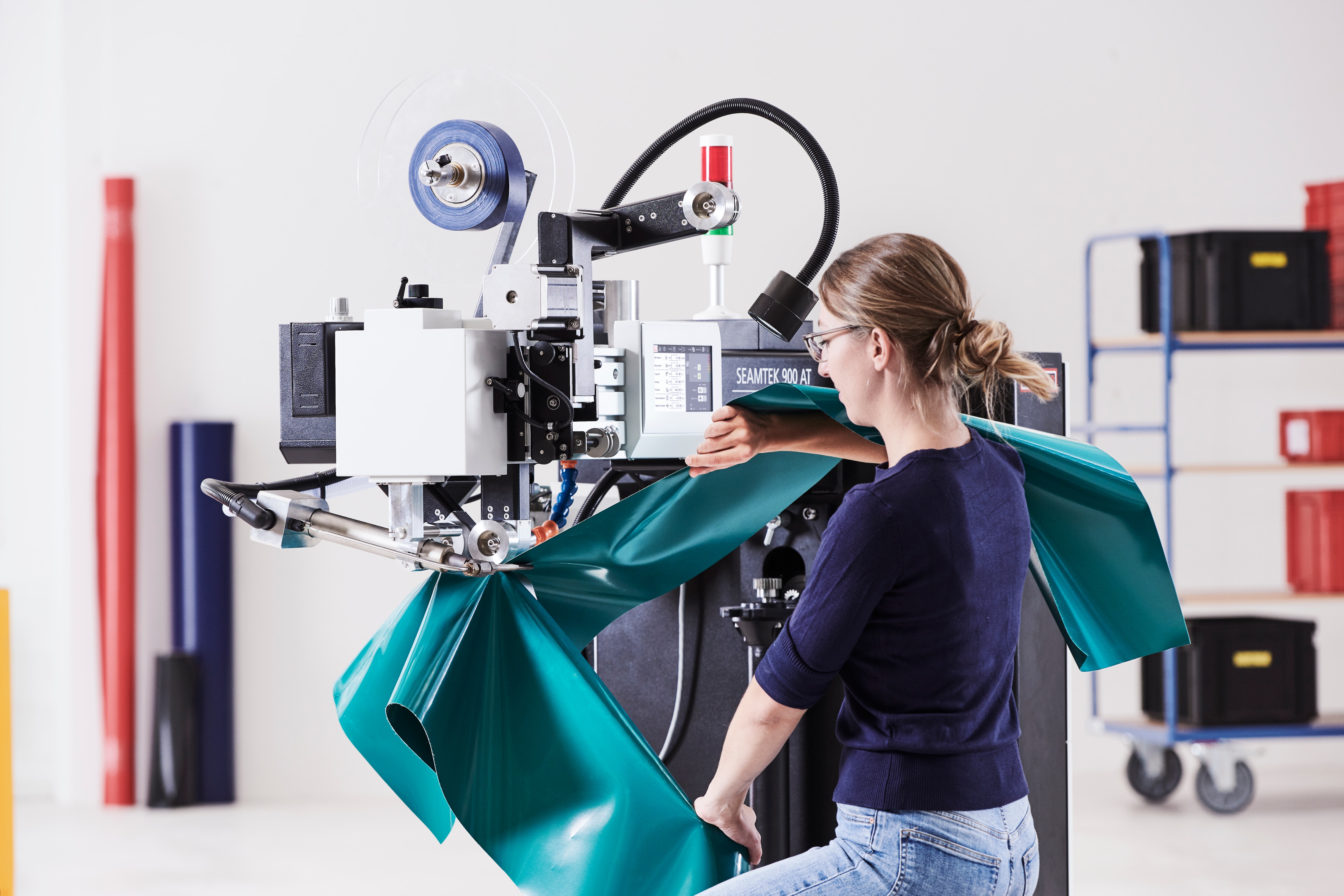

Welding Technical Textiles? SEAMTEK W-900 AT.

Save energy in standby mode with the SEAMTEK W-900 AT: conventional welding machines are in standby mode for around 80 % of their operating time on average and continuously consume considerable energy. As the wedge of the SEAMTEK W-900 AT is ready for use within seconds, you switch it off completely when it is pivoted out, thus saving significant energy.

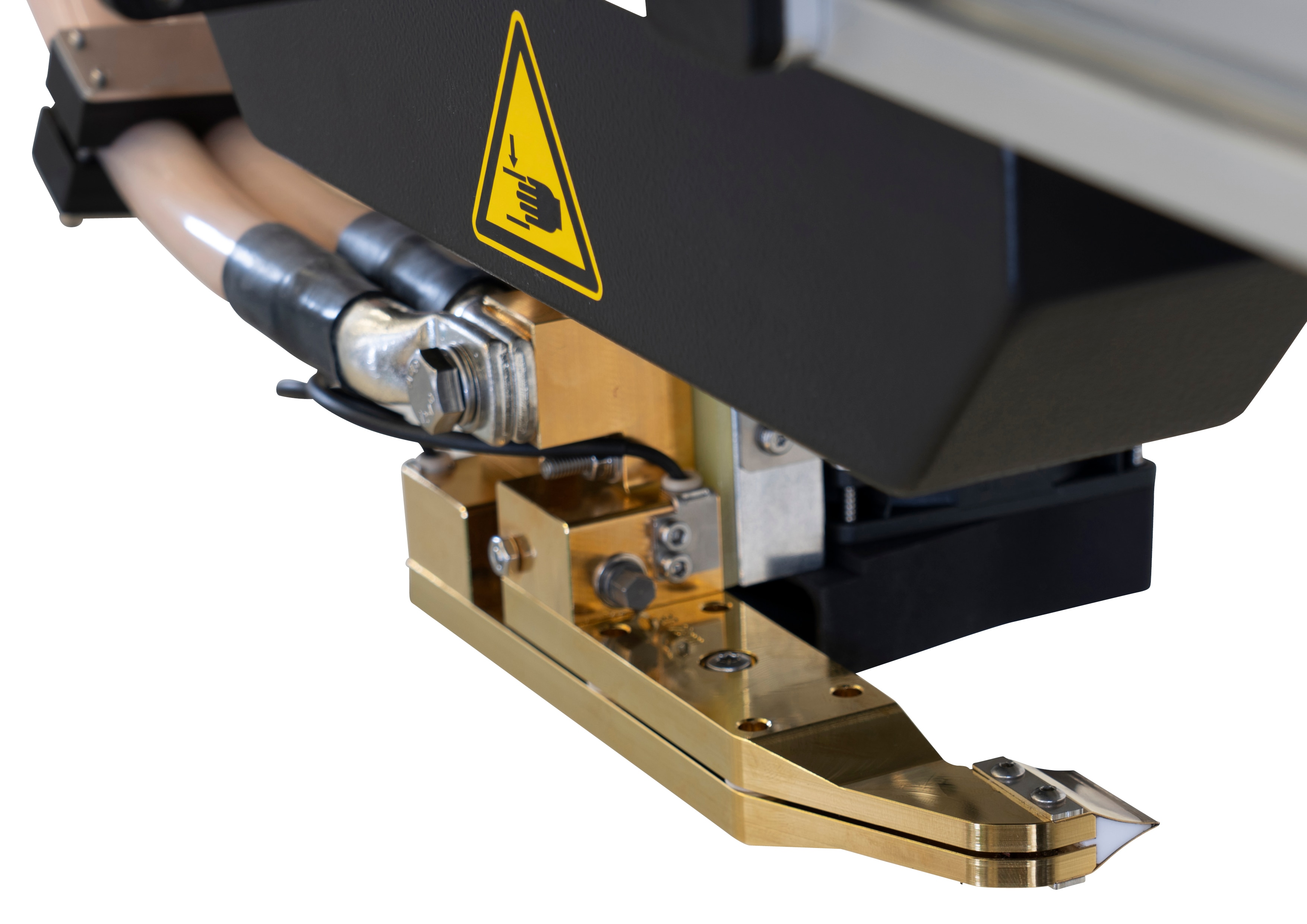

The only wearing part of Leister’s SEAMTEK W-900 AT is an inexpensive wedge. Forget expensive heating elements, aluminum wedges, thermocouples or tedious grinding in of the wedge. All bearings and guides are also low-maintenance. All this saves you costs and minimizes your maintenance requirements.

As the wedge plate is very small, you regulate the temperature of the wedge in fractions of a second. You adjust the speed flexibly during the welding process according to your experience and the complexity of the products. If required, higher speeds can be achieved than with hot air welding or high-frequency welding due to the high energy density at the wedge.

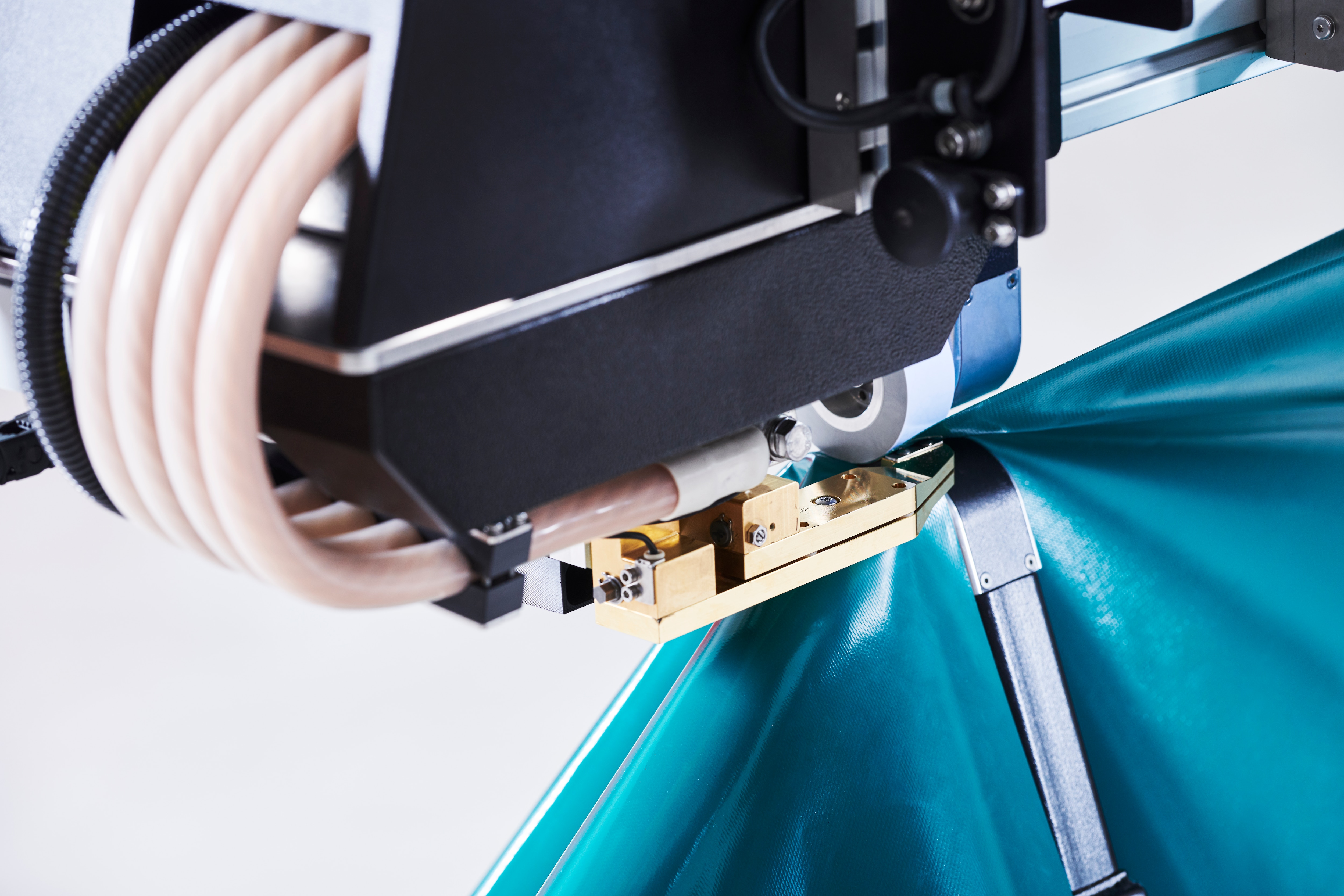

Precise and fast control of the energy at the wedge allows precise maintenance of the operating point. This makes the welding process virtually emission-free and very quiet as no flowing air is required. With low-voltage hot wedge technology, only the wedge plate is heated to a high temperature. All other parts in the welding zone remain outside. This removes the risk of burns and makes your work environment safer.

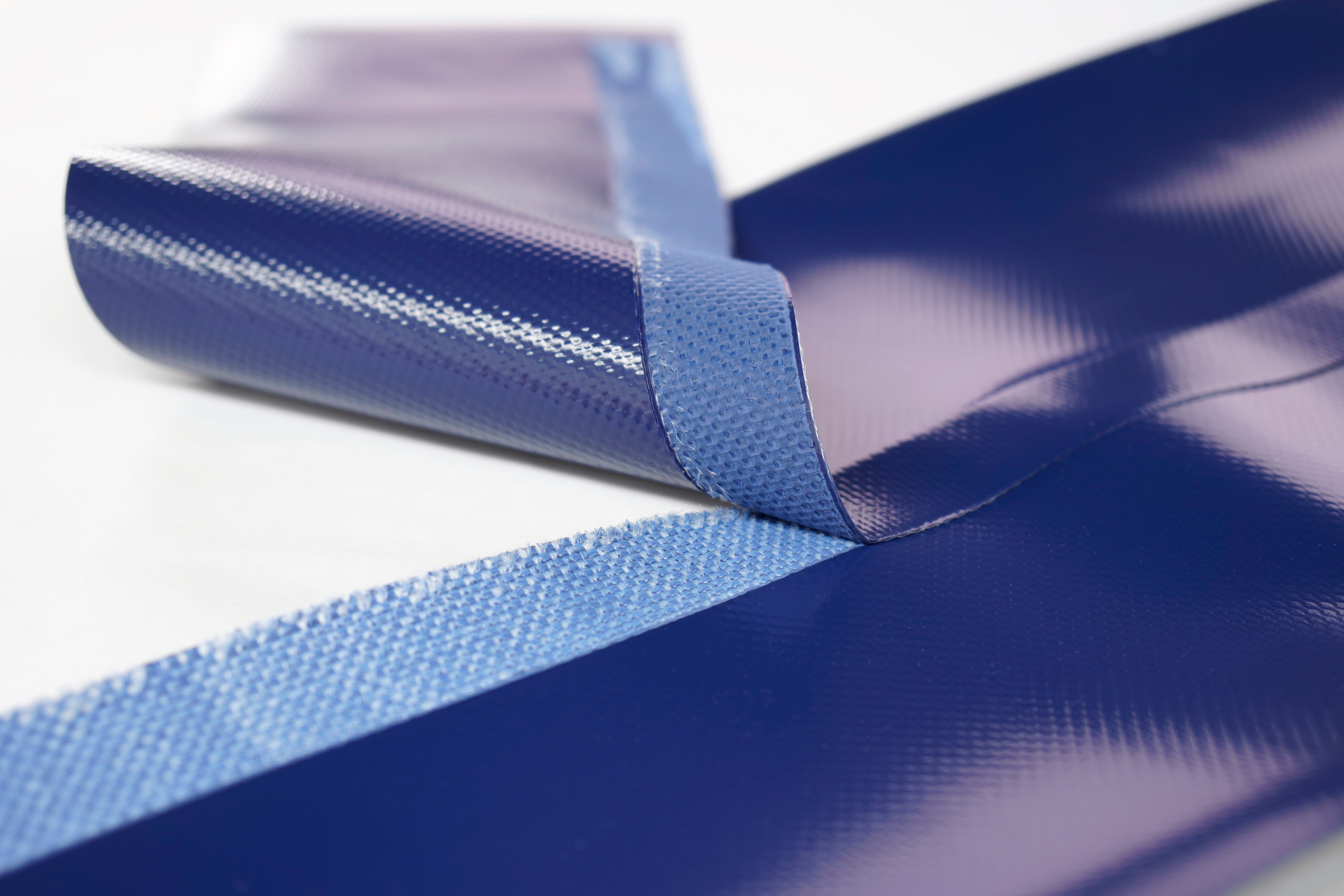

When welding with the SEAMTEK W-900 AT, you apply the energy precisely where needed, i.e. directly in the welding zone. This allows you to achieve aesthetically pleasing welding seams.