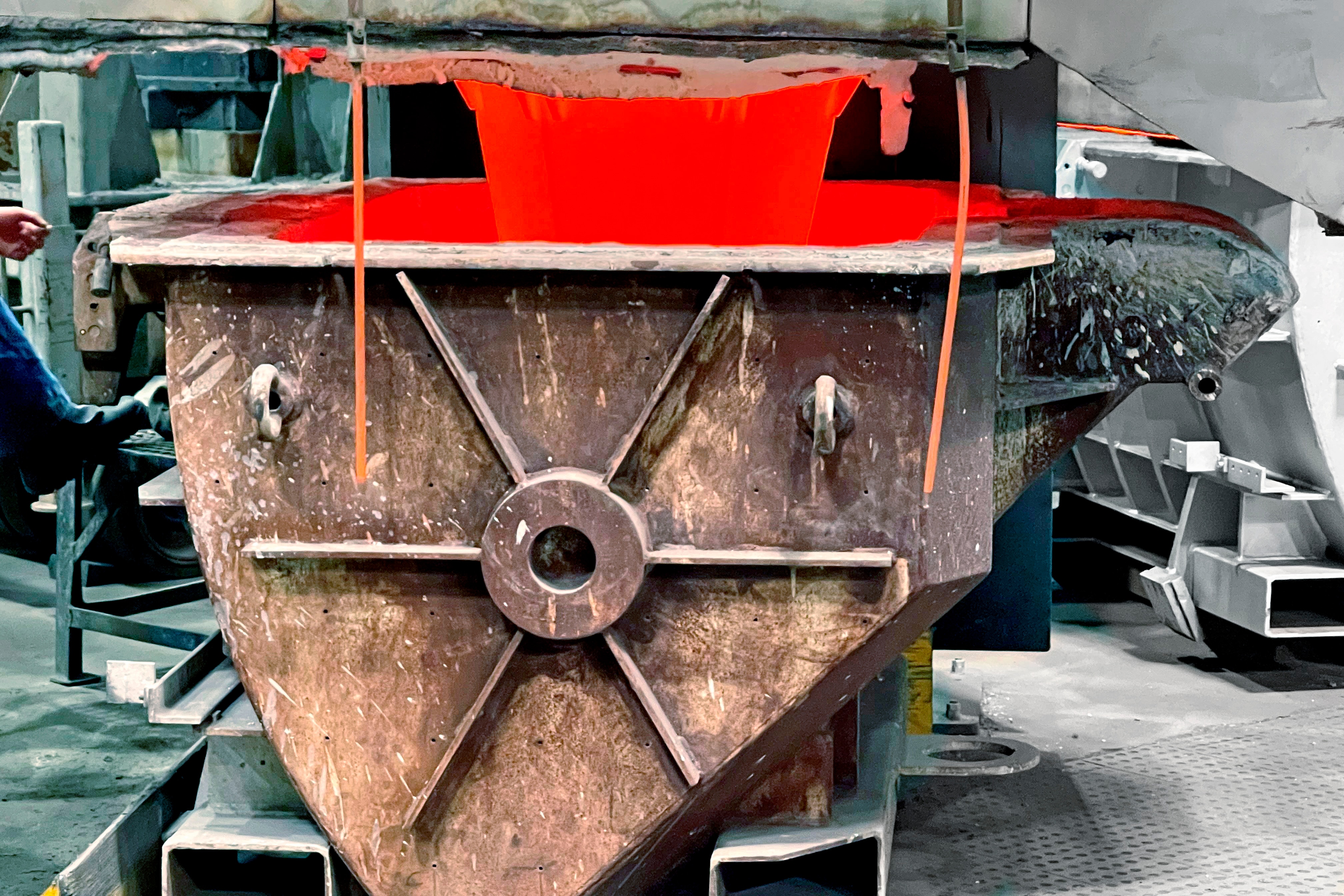

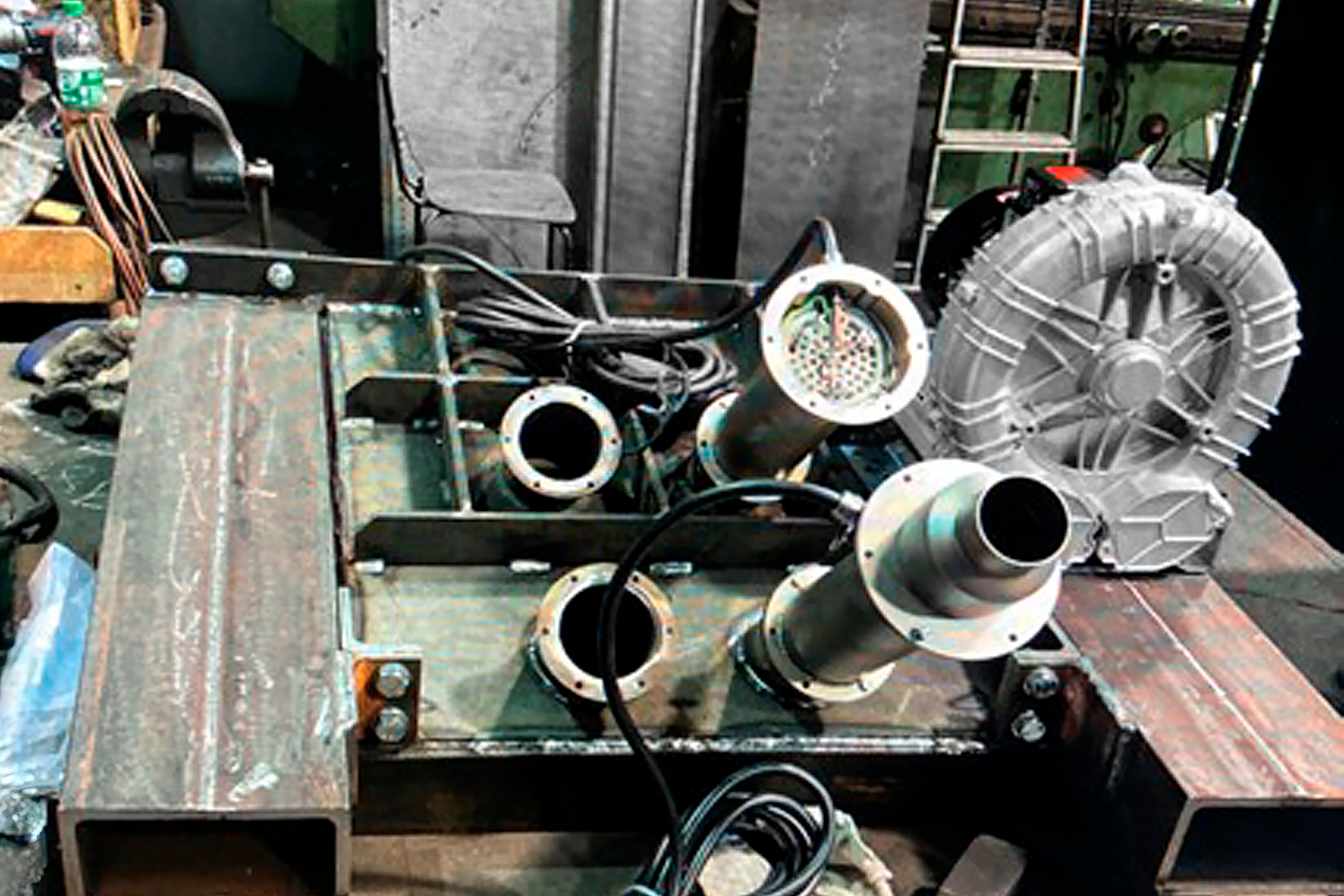

Each of the four LE 10000 HT air heaters has an output of 22 kW and two AIRPACK fans for optimum air circulation. To prevent overheating, each air heater is controlled by a thermocouple to ensure a stable process. The compact design allows easy installation above the opening of the heat treatment process, placed on insulation and lifted with a forklift.

Before the introduction of this innovative solution, the minimum output was 450 degrees Celsius with a drying time of 70 hours. This technology makes it possible to preheat the converter using the Leister system in the event of a shortage of natural gas.

Savings of up to 200 kW Natural Gas

In total, the 88 kW Leister air heaters replace up to 200 kW of natural gas, which not only leads to considerable cost savings, but also minimizes the environmental impact of the process. This groundbreaking solution underscores Leister's commitment to working with partners like GF Casting Solutions to develop innovative technologies that redefine industry standards and promote a sustainable future.

About GF Casting Solutions

GF Casting Solutions is a globally active company with the divisions GF Piping Systems, GF Casting Solutions and GF Machining Solutions. Since its foundation in 1802, GF Casting Solutions has been a pioneer in the development and provision of innovative products and services for a wide range of industries. www.gfcs.com