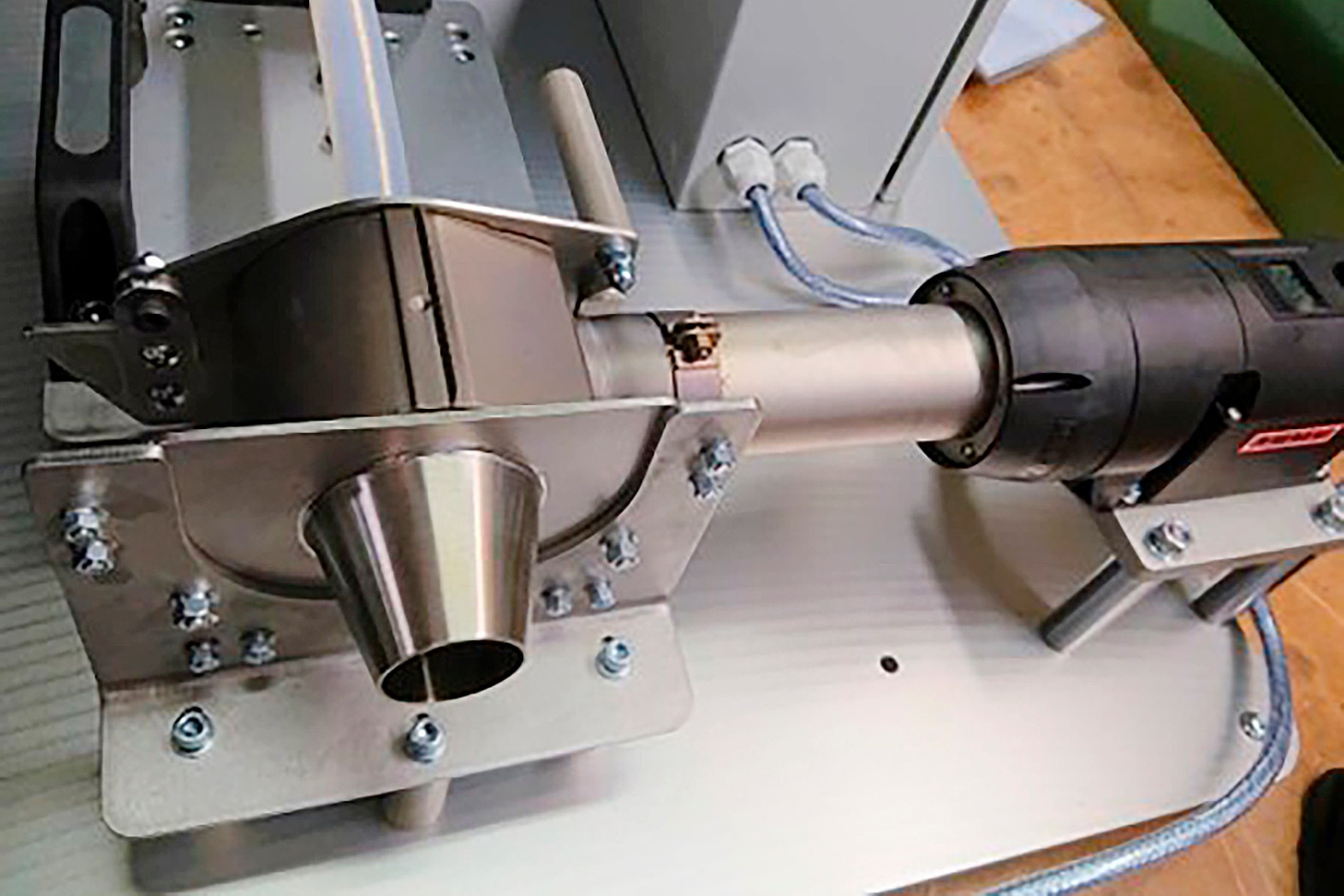

The hose heating device with the integrated MISTRAL 6 SYSTEM hot air blower from Leister proved to be a pioneering game changer. Tested on four different hose sizes, this device transferred the hoses directly from the heat source to the spin forming and press quenching stations and delivered the desired results. This innovation marked a significant departure from the dangerous salt bath method and led to a safer and more efficient "dry" heating technology.

Industry-wide interest aroused

The success of this new approach led to the formation of a global task force by one of TF Automation's customers, highlighting the industry-wide interest in adopting this dry heat/forming process. Spurred on by this enthusiasm, TF Automation is currently developing specifications and offers for the first automatic heating, forming and press quenching machine. This machine is on the verge of merging four previously manually intensive and cumbersome processes into a single, optimized operation.

To further improve this innovation, the 4500 W MISTRAL 6 SYSTEM hot air blower from Leister was combined with a 70×70 mm hinged reflector nozzle. This combination proved to be very effective for the different hose sizes tested. The next step involves the introduction of a hot-air tool into a fully automatic machine. This is equipped with advanced functions. This includes temperature and air flow adjustments, controllable via a PLC. The machine also has displays for these parameters. It enables automatic setting adjustments, depending on the hose size. Important safety measures are also integrated. These include alarms for temperature drops and a mandatory cool-down mode.

Further development with VULCAN SYSTEM 6 kW from Leister

For the production of larger hose models, TF Automation recommends the VULCAN SYSTEM 6 kW hot air blower from Leister. The compact fan is characterized by its enormously powerful heat and air flow performance (6 kW). In addition, its dimensions allow easy installation in industrial systems. The hot air blower can also be controlled remotely via standard analog interfaces.

As TF Automation and Leister continue to push the boundaries of hose manufacturing technology, their shared commitment to innovation, efficiency and safety stands as a beacon project for an entire industry and heralds a new era of manufacturing excellence.

About TF Automation

TF Automation is a company that specializes in the development and manufacture of process automation solutions. TF Automation is known for its expertise in engineering and machine manufacturing and serves a wide range of manufacturing industries. TF Automation is also a supplier of pneumatic and industrial components. tfautomation.co.uk