Author: Vivek Subramani, Marketing Manager, Leister Technologies India

Skyroof Enterprises from Bangalore has been active in the production of tents and tension fabrics for over 16 years. The company specializes in what is known as pagoda constructions in various sizes. These are tent designs whose main feature is their highly pointed roof shapes. “We supply both large companies and private customers throughout India, from the peaceful valleys of Kashmir to the vibrant coasts of Kanyakumari,” explains CEO Suresh Chellam.

Innovation meets Tradition

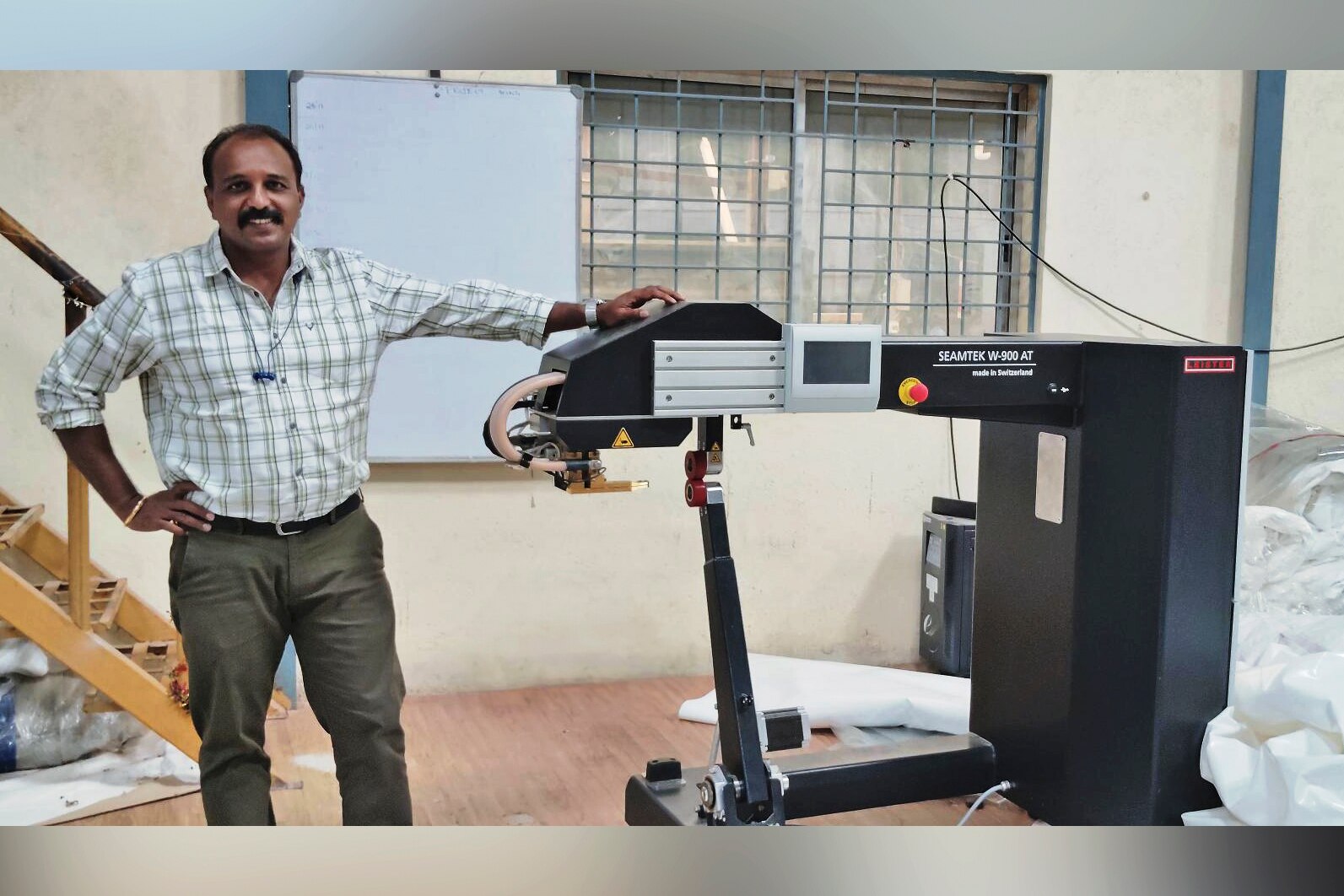

In recent years, Skyroof Enterprises has relied on high-frequency welding machines for its tent production. However, to achieve better efficiency and higher production capacity, an innovative, faster welding machine had been on the agenda for some time. Being able to realize a major project as quickly as possible was the catalyst for switching to SEAMTEK welding machines from Leister.